External Visual Inspection (Check for external package defects)

Failure Verification (Verify / validate test failure)

X-ray Analysis (Check for bonding defects)

CSAM Analysis (Check for any delamination, die crack, package voids, etc.)

Fault Isolation Technique (Isolate or locate the defect)

SEM Inspection (Search for zoom-in defects)

Internal Visual Inspection (Die VI to search for defect)

De-capsulation (Expose the die surface)

Polishing Technique (cross-sectional or parallel polishing to identify the defect)

Elemental EDX Analysis (identify elements present on a certain materials)

Re-balling (For BGA devices that undergone board removal)

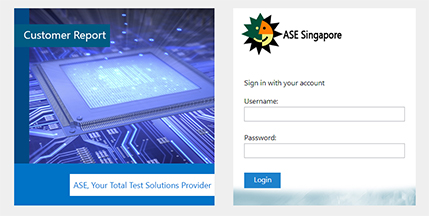

Customer Report

Temperature wafer sort from -40 to 130C

Multi Site Probing up to 32 Sites

Low K Wafer Probing , 65nm

Bump Probing with Vertical and Membrane Probe card(Eutectic / Pb Free / High Lead bump)

In-line yield monitoring via UTHIP(Running Yield / SBL / S2S / OEE)

Internal probe card maintenance, probe pin replacement

RF Probing via Direct Dock Solution

PAT ( Part Average Test ) – Stack wafer maps analysis

Top and Bottom Package Visual Inspectionn / PVI

2D and 3D Measurement

Add mark (Laser)

Tape and Reel

Auto Bake Oven system

Machine

Model

STI

HEXA

ICOS

T120

T130

T220

IC9450

MIT

TH800Vix

Receiving

Incoming check-Camtek Falcon

Taping-Lintec RAD 3510F/12

Backgrind-Disco DGP 8560 (12”)

Detaping-Teikoku EXR2-1200CSF2-UV-CE(12”)

Wafer Backside Lamination-RAD 3600

Oven tape cure

Laser mark-EO Technics CSM3000

Wafer mount / Frame link-Lintec RAD2500F/12

Laser groove-Disco DFL7161

Wafer saw-Disco DFD6063A

2D Inspection-Camtek Condor

Tape and reel-STI ISORT MAXX

Packing and labeling

Out-going check

Shipping

ATC capability (-40 to 130C)

Package range (Testing within ASESG)

Outsource Burn-in Locally-Aehr Oven (Static Burn-in)

Special device requirements-Unique Key ( Flash & OTP Verify)

Software tools ( Under evaluation )Streetwise ™

Support Single, Dual, Quad, Octal capabilities base on different tester platform subject to ASESG availability

Tri –Temp Testing (-50 ◦C to 150 ◦C)

Multi Site Testing : Up to 16 sites

Major package type FCBGA, HSBGA, PoP, aQFN, QFN & TQFP Package size(mm) 3×3 ~ 67.5×67.5

In-house Hardware Repair Labs, Hardware control automation

In-Line Yield Monitoring via UTHIP System-Running Yield/SBL/UPH/Down Time/OEE / S2S

Working knowledge with wide spectrum of hardware sockets (eg: ECT, MJC, Johnstech, Foundpac, IDI, etc)

Total Burn-in Solution via Controlled partnership with Burn-in house

Special device requirements/flows(Unique Key ( KSV, OTP & Security code),E-fusing, Flashing Speed Binning Bench Testing/SLT)

ASESG is a qualified suppliers under

12,000 sq ft of warehousing spaces

24×7 FGI break bulk drop shipment operation to worldwide destinations.

Daily inventory and transaction reports access thru B2B or Web Portal